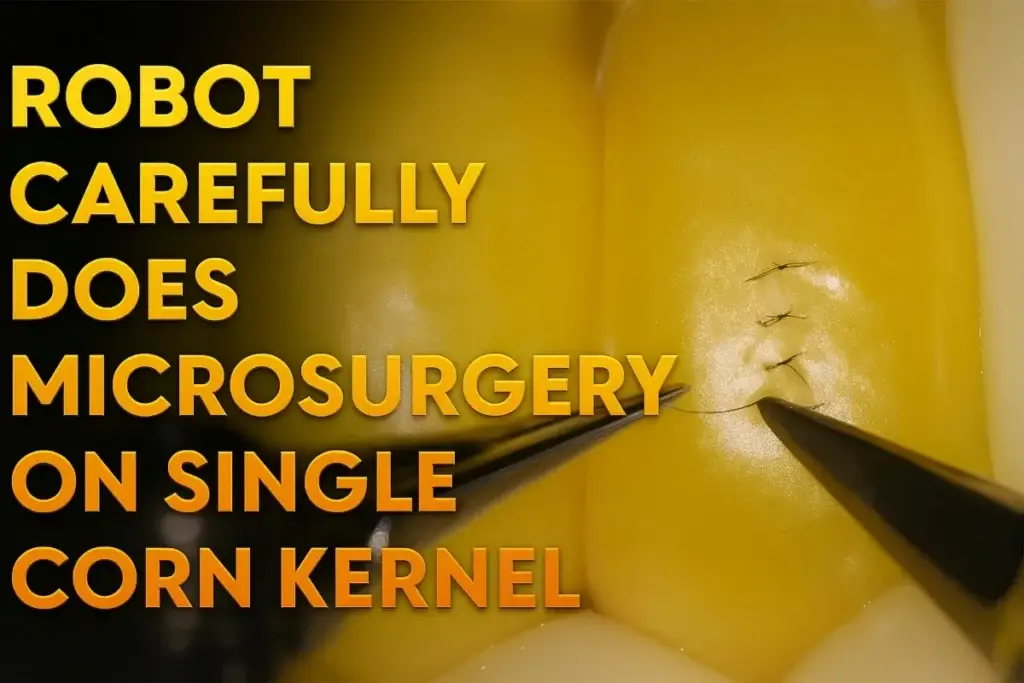

A Robot Sewed a Corn Kernel and It Could Revolutionize How We View Surgery

It’s so straightforward, it’s almost too significant. A machine passes a needle through the thin flesh of an ear of corn. No flashing lights. No swelling sound effects. Just a slow, deliberate hand doing something that, hitherto, appeared to be the exclusive domain of humans. But there is a narrative behind this small action about the future of surgery. One that is less about flash and more about the slow, meticulous work of repair.

This was no marketing stunt or laboratory test for effect. It was all part of a continuing attempt by Sony to create surgical aid technology that can actually benefit physicians at the most critical cases. And the corn kernel was their proof-of-concept.

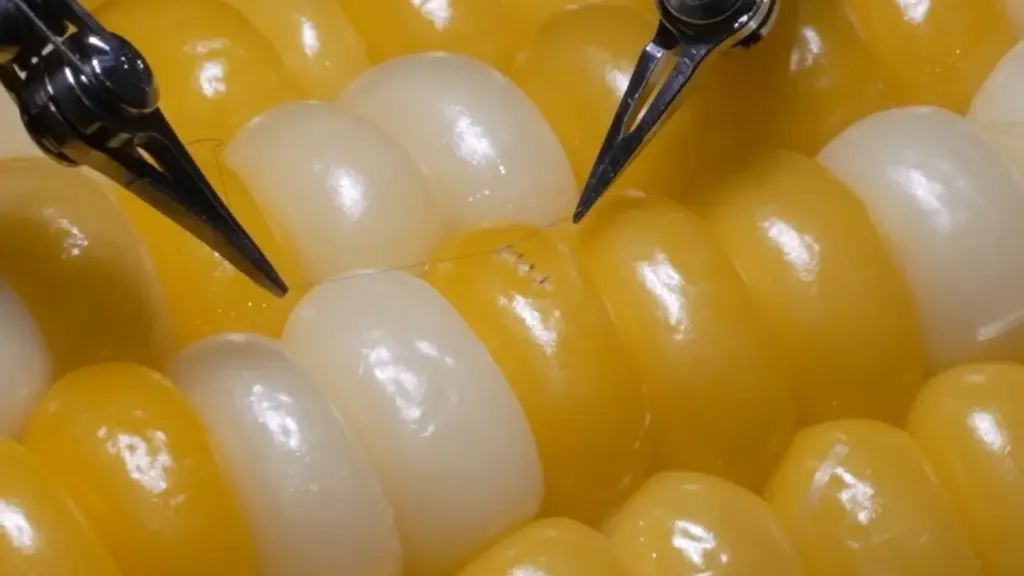

Why a Corn Kernel?

It might seem strange at first, but corn kernels have become a handy model in microsurgery without anyone even noticing. They are firm but soft, readily accessible, and small enough to give the practitioner a sense of handling minute human tissue. While practicing on a kernel, researchers are actually developing the delicate motor skills that may be required to sew blood vessels or nerves that are sometimes less than a millimeter in diameter.

This was confirmed in a 2022 study by Fernandes and others. It demonstrated that corn grains provide a low-cost and convenient to employ model for training. So when Sony decided to prove their robot’s accuracy with a kernel, it wasn’t a novelty act. It was an actual benchmark.

If a robot can sew something that small and that fragile, it creates possibilities well beyond the laboratory bench.

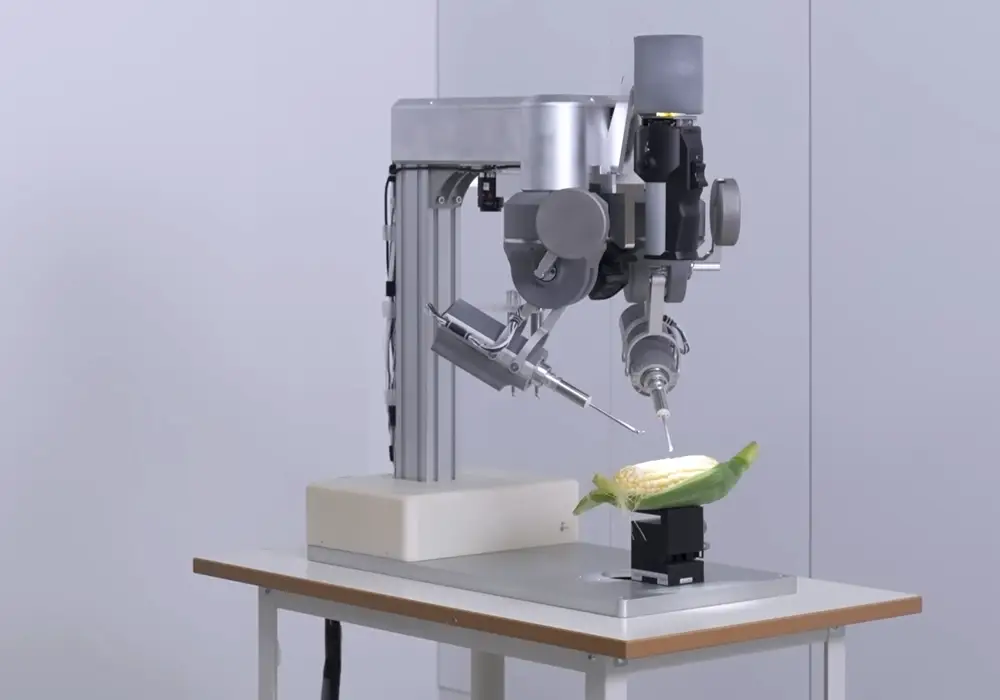

How the Robot Operates

Hiding in the middle of the demonstration is a robot that doesn’t think. It does not take the place of the surgeon. Rather, it improves their skills. Surgeons utilize a set of accurate hand controllers to maneuver the robot forward, and what they observe is amplified via a high definition 3D display.

As the surgeon moves, the robot reacts. But in a more steady, more precise manner than a human hand can accomplish independently. A big motion with the hand translates to a much smaller, more precise motion with the robot. This is important when working with instruments as delicate as the 12 0 suture needle, one of the slenderest available in surgery.

To put that into perspective, a 12 0 suture is finer than a human hair. Working with it demands intense concentration and muscle control. That’s where the robot shines. It handles the tiny, fragile materials without shaking, slipping, or tiring.

Beyond the Lab

What adds significance to this project is the fact that the project has been extended beyond laboratory demonstrations. Sony has even tried out this robot in preclinical trials with Aichi Medical University, where it assisted in actual surgical situations with animal tissues. In the trials, the robot played a part in operations such as reconnecting minute-sized blood vessels, a skill that one needs in reconstructive surgery and other high precision procedures.

The fact that it functioned successfully under such conditions is an indication that this technology is not merely a prototype. It is something that may someday be used in operating rooms, especially where very experienced microsurgeons are scarce.

Consider a small city or rural hospital that can’t afford to have a full-time specialist on staff. A general surgeon who’s been trained, aided by a robot like this one, could do procedures that otherwise would be referred to a large center. That might equate to quicker treatment, less travel, and improved outcomes for patients.

Why It Matters

There is a subdued sort of beauty in seeing this robot in action. It does not speed or make big movements. It does not overpower the task. It merely assists the surgeon, providing stability and accuracy where it can be most valuable.

This method also steers clear of the typical apprehensions that accompany medical robots. It is not attempting to make decisions or diagnose illnesses. It is a tool, a highly intelligent and elegant tool, but a tool. And perhaps that is its greatest advantage. Trust in medicine is built over time. A robot assisting surgeons instead of taking their place might be less challenging for doctors and patients to accept in the room.

Conclusion

A picture of a robot sewing a corn kernel is not necessarily earth-shattering at first sight. But the very best innovations are sometimes those that function discreetly behind the scenes. They do not call for public notice. They do not require headlines.

They simply get the task accomplished, methodically and steadfastly.

With Sony’s microsurgery robot, that work starts with a kernel of corn and extends to a future when sophisticated surgery is safer, more available, and a little more human than we might have imagined.

For more read my latest blogs, thank you.